The polymer industry has become one of the most dynamic and technology-oriented industries in the contemporary manufacturing industry. At the back of its development is the perpetual innovation that is provided by all the masterbatch manufacturers. Masterbatch is an essential part of the plastics industry as it allows the effective coloring, stability, and enhancement of performance of different materials. From automotive parts to consumer products, the world of polymer processing is largely due to the innovativeness and professionalism of the masterbatch manufacturers, who have been keeping pace in the field of material science.

- Polymer Processing Role of Masterbatch

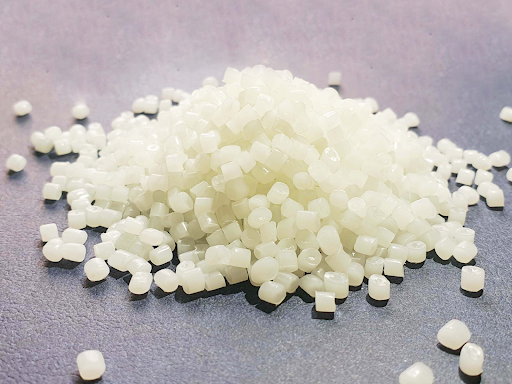

Masterbatches: Masterbatches are concentrated compounds of pigments and additives that are mixed with raw polymers to provide them with a certain characteristic. A masterbatch producer also makes sure that the mixture is formulated so that it is easily dispersed during production. With the process, it becomes possible to obtain a uniform distribution of colour and required material properties without reducing the quality. Masterbatches in the modern manufacturing industry ease the manufacturing process, minimise wastes and ensure consistency, and it is therefore necessary in the production of durable and high-quality plastic goods.

- Novelty by Improvement of Material

The uses of polymers in the present world extend to more than mere plastic production. The industries have become in need of materials with heat resistance, chemical resistance and exceptional mechanical strength. This is the point at which the innovation of masterbatch manufacturers is really brilliant. They are ever researching and coming up with new formulations that suit the needs of the various sectors of industry. An example of this is a plastic Nylon masterbatch that improves the toughness and flexibility of nylon compounds and is therefore applicable in the case of engineering parts, textiles, and packaging solutions. With these developments, manufacturers are able to produce materials of high quality to be used in the current application.

- Eco-Friendly and Sustainable Developments

The last few years have witnessed a change in the polymer sector towards sustainability and environmental responsibility. Masterbatch producers are responding to this shift by developing environmentally friendly solutions that minimize plastic waste and encourage recycling. The recent innovations include bio-based colourants, biodegradable additives, and recyclable polymer blends. These innovations not only contribute towards the conservation of resources but also give hope to the industries that are willing to match the green standards. Manufacturers are demonstrating through their constant research that environmental care can coexist with innovation in polymer processing.

- Technology and Efficiency

The other significant change in polymer processing is the introduction of modern technology. The accuracy of batch and reduction of errors in production are now ensured using precise equipment and automation in a masterbatch manufacturer. High-performance masterbatches can now be produced with modern extrusion technology in a more efficient and quicker manner. This will not only increase the volume of output in the production process but also provide customers with a uniform quality of the product. The industry is also establishing new standards in quality in terms of manufacturing polymer excellence, with real-time monitoring of quality and sophisticated methods of blending.

Conclusion

In the modern industrialized high-speed environment, masterbatch manufacturers continue to be the pacesetters in the evolution of polymer processing. They are committed to research, quality, and sustainable innovation, which has changed the potential of plastic engineering. With the continuously resilient process of manufacturing adopting innovation and greener technology, the input of all progressive masterbatch producers will continue to be placed at the centre of creating a smarter, more robust and more viable future of the polymer sector.